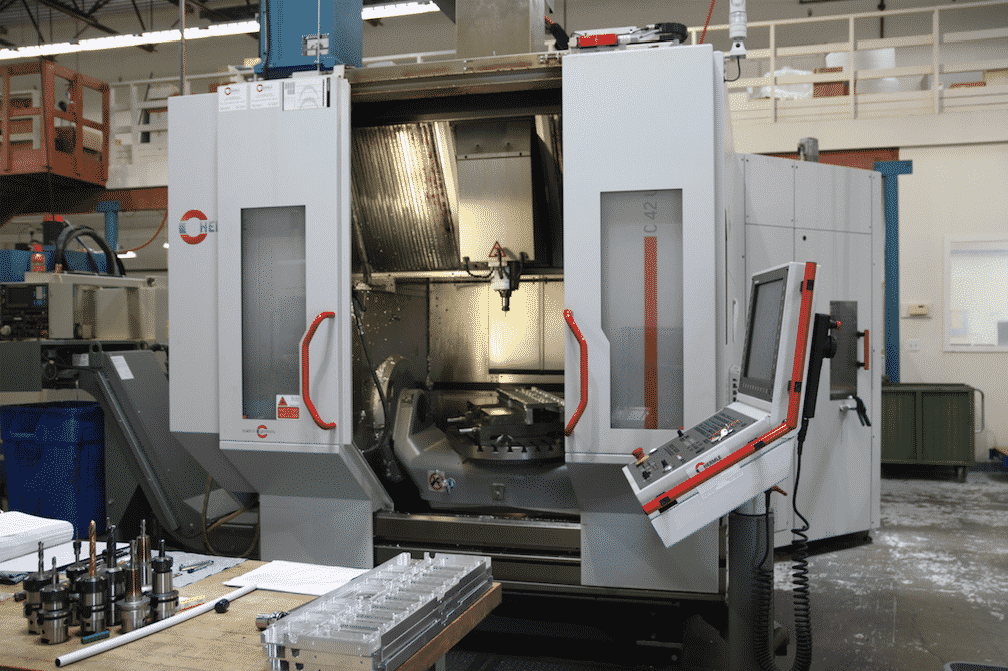

Our machines are all CNC controlled and have 3-axis, 4-axis, and 5-axis capabilities to machine hard metals with a 31.5 inch (800 mm) by 40 inch (1016 mm) work envelope.

| Equipment Type and Spindle Capacity | |||

| CNC Machining Centers | Part Size | Spindle RPM | HP |

| Hermle C30 U 5-Axis Machining Centre | 25″ x 23″ x 19″ | 18,000 | 15 |

| Hermle C42 U 5-Axis Machining Centre | 31.5″ x 31.5″ x 21.5″ | 18,000 | 27 |

| Hermle C600 U 4-Axis Machining Centre | 23″ x 17″ x 17″ | 16,000 | 15 |

| Hermle C600 U 4-Axis Machining Centre | 23″ x 17″ x 17″ | 12,000 | 15 |

| Okuma LB 3000 EX Lathe, Live Tooling | 10″ DIA x 22″ | 6,000 | 30/20 |

| Okuma LB 200 Lathe, Live Tooling | 10″ DIA x 18″ | 6,000 | 10 |

| Okuma LB10 Lathe | 10″ DIA x 18″ | 6,000 | 10 |

| Okuma MX55 #50 Taper Vertical Mill | 41″ x 22″ x 17″ | 6,000 | 15 |

| Okuma MX2 Vertical Mill | 29″ x 18″ x 17″ | 7,000 | 10 |

| Okuma MX1 Vertical Mill | 29″ x 18″ x 17″ | 7,000 | 10 |

| Roku K3 Vertical Mill | 20″ x 18″ x 10″ | 5,000 | 7 |

| Roku G Vertical Mill | 20″ x 18″ x 10″ | 12,000 | 5 |

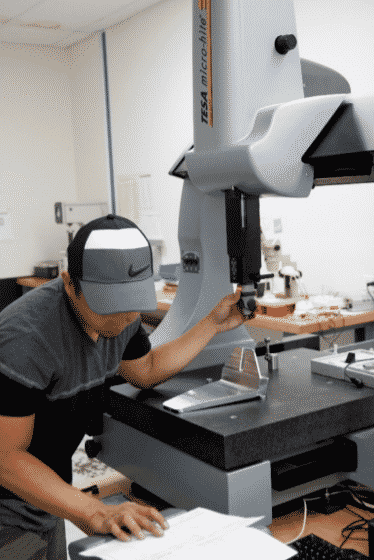

Our philosophy is that behind each machine, quality is based on the individuals that operate them. We invest heavily in human resources and our staff are fully trained and cross-trained to ensure consistent performance.

Our Inspection Room is climate controlled 24/7 at 20° Celsius

or 68° Fahrenheit.