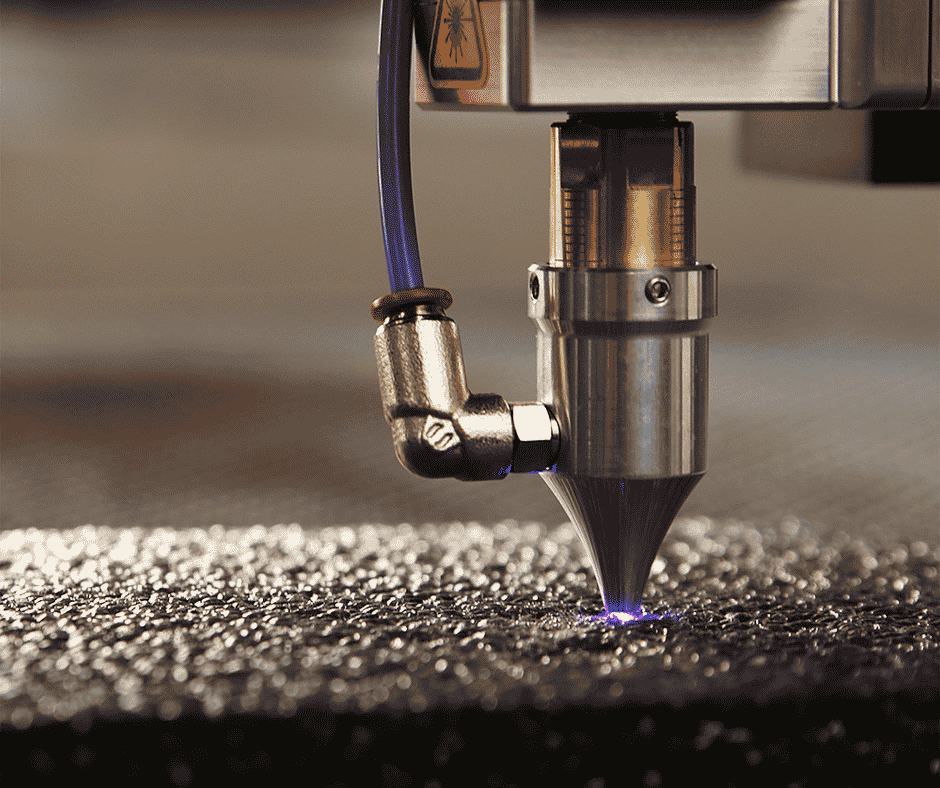

As industries continue to evolve at record speed, precision commercial machining is entering a new era in 2026. It is one defined by tighter tolerances, smarter production methods, and increased collaboration between manufacturers and clients.

Precision Commercial Machining in 2026

At Zum Hingst Technologies, we are committed to ongoing shifts in precision commercial machining, helping businesses of all sizes stay competitive through advanced solutions – which includes…

Greater Adaptability and Scalable Production

In 2026, companies can expect precision machining to become even more adaptable. Whether you require low, medium, or high production quantities, flexible manufacturing systems will play a larger role in meeting diverse commercial needs without sacrificing quality or turnaround time.

ZHT already operates with this agility, allowing our customers to scale quickly and efficiently as their project demands change, but we never shy away from continual growth.

Rising Demand for Cost-Efficient Machining

With material and operational expenses increasing across many sectors, 2026 will bring a stronger focus on cost-efficient machining strategies. Manufacturers are placing greater emphasis on improving the manufacturability of each part, while reducing waste, enhancing performance, and lowering production costs.

Our team has decades of experience optimizing part designs and machining processes, and we’re proud to apply knowledge gained from serving a wide range of specialized commercial industries.

Enhanced Collaboration Between Clients and Machinists

Stronger collaboration will continue to shape the future of commercial CNC machining. At ZHT, we work closely with our customers to understand their goals, challenges, and timelines. This partnership-driven approach allows us to recommend improvements that support product reliability, streamline production, and maximize value.

It’s one of the reasons our consistent performance has earned long-standing trust across multiple commercial sectors.

Expanding Access to Advanced CNC Technologies

2026 also will bring with it – greater access to high-precision CNC technologies. From complex components to high-volume production runs, advanced machining capabilities are becoming essential for staying competitive.

By partnering with our machining team, who continuously invests in staying ahead of emerging trends, businesses can ensure they remain innovative and production-ready.

Partner With Zum Hingst Technologies for Commercial Machining in 2026

If you’re ready to learn how precision commercial machining can support your goals in 2026, contact Zum Hingst Technologies today to discuss your project, or inquire about our advanced CNC services. We’re here to help you stay ahead of the curve with reliable, high-performance machining solutions.